Application of innovative bonding technology

Today, it is impossible to imagine special automotive machine construction without the bonding of components. The range of applications and possibilities for this process offers many advantages, but also requires a high level of expertise and know-how.

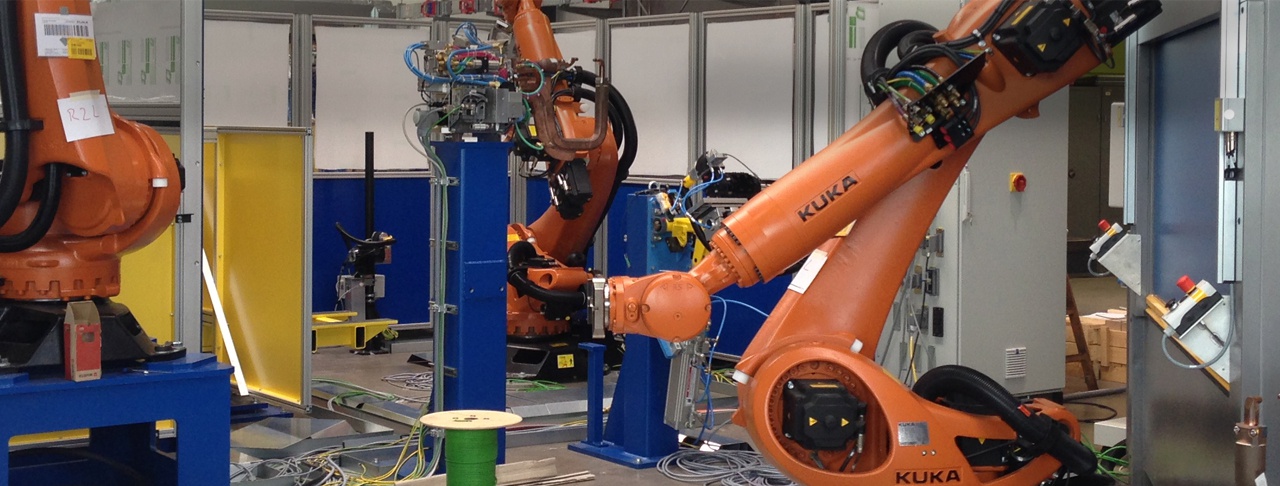

At IMP, we have been involved with various bonding techniques from an early stage and today, as developers of innovative production processes, we can draw upon a substantial wealth of experience which enables efficient, reliable and intelligent production.

The creative implementation of all customer specifications is always in the foreground during the entire development process. Our customers are aware of our excellent contacts to a wide range of suppliers in the field of bonding technology. All components brought together, our customers always get the best variant of robotics, bonding and dispensing technologies and individual programming.

Bonding technology at the highest level

At IMP | Innovativer Maschinenbau Pfeifer is known for its creative solutions in the special machine construction for the automotive industry and stands for the advanced connection of different applications with one another.

The customer gives us the specification, we find the solution and also at the same time develop the implementation, plan the systems and also produce them.

Regardless of the individual technology used - we are well versed in bonding techniques.

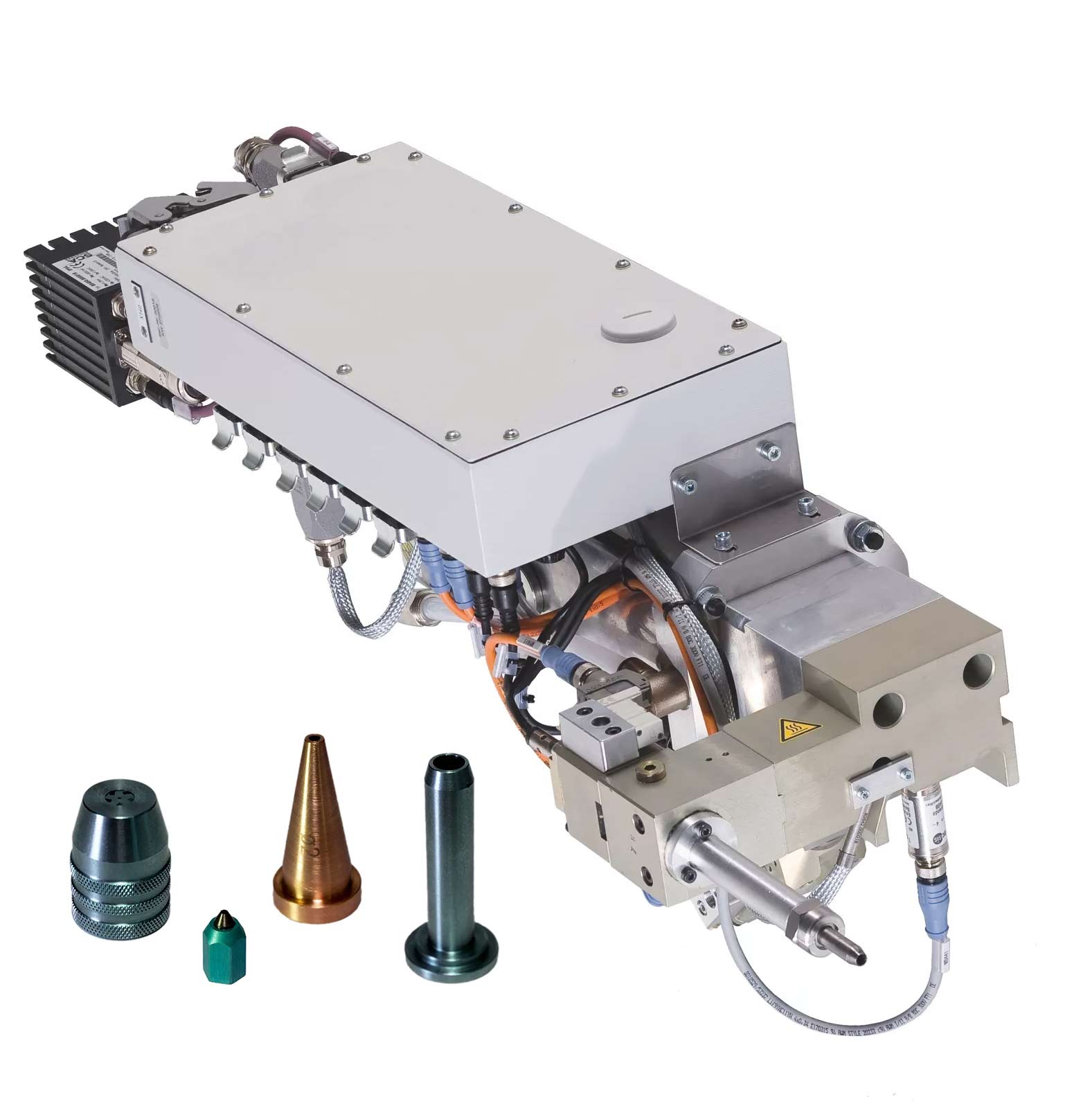

Choice of the best components,

for safe production.

IMP engineers are well aware that the bonding applications developed by us run in production environments which operate on a 24/7 basis.

That is why we have a high level of quality awareness whenever it comes to the reliability of the components used by us. In combination with the easy handling, high machine availability and excellent quality of the results, which is in no small measure due to the experience of our programmers, our special machines are a highly rewarding purchase.

It does not matter to us whether we are dealing with cold or heated, one or two-component adhesives. The requirements of our customers in terms of crash safety, lightweight construction or short production times, to name but a few, are decisive as far as we are concerned.

Imaginative solutions in special machine constructionOur many years of experience in the application processes make us experts upon whom you can rely. |

|

|

Underbody, roof, framing or add-on parts

The variety of applications in the automotive bodyshell is large and can be very different for different component groups.

Our expertise lies in replicating the specifications of our customers precisely and in a reproducible manner in an industrial environment.

Using bead, lockstitch, swirl, support bonding, multi-point or multi-axis applications in conjunction with other technologies requires a great deal of experience and expertise.

Our expertise in the use of bonding applications in combination with other technologies, such as spot welding or different types of bonding, such as bead or lockstitch applications, makes IMP's systems so effective.

There is a lot of potential in bonding components

We know the challenges which have to be solved when bonding different materials and substances to form a new vehicle component.